Spring Design: Spring Squareness, Parallelism and Grinding

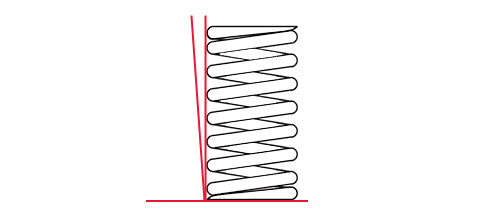

Spring Squareness

Spring squareness is the angular difference between the outermost limit of a spring diameter when compared to a straightedge at a right angle to a horizontal flat plate on which the spring is standing. This affects how the axial force produced by the spring can be transferred to adjacent parts in a mechanism. Open ends may be entirely suitable for some applications, however, when space allows, closed ends provide greater squareness and reduce the possibility of tangling with little increase in cost. Compression springs with closed ends can often perform well without grinding, particularly in wire sizes smaller than .020 in. or with a spring indices exceeding 12.

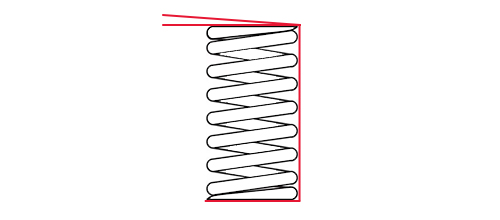

Spring Parallelism

Spring parallelism relates to the ends of the spring and how parallel they are to one another. A compression spring cannot be closed and ground so consistently that its ends will always be square (in parallel planes at right angles to its axis). In addition, the helix angles adjacent to the spring end coils will not have uniform configuration and closing tension, and these springs cannot be coiled so accurately as to permit all coils to close out simultaneously under load. As a result of these end coil effects, the spring rate tends to lag over the initial 20 percent of the deflection range, often being considerably less than calculated. As the ends seat during the first stage of deflection, the spring rate rises to the calculated value. In contrast, the spring rate for the final 20 percent of the deflection range tends to increase as coils progressively close out.

Spring Grinding

Many applications require grinding the spring ends to provide greater control over spring squareness. Spring grinding is a process used during the manufacture of springs to shape the end coils to a flat or square shape.

Spring grinding and spring squareness may be important to spring designs under the following conditions:

- High Quality spring applications

- Close spring tolerances on load or rate are required

- Solid height must be minimized

- Accurate seating and uniform bearing pressures are required

- A tendency toward buckling must be reduced

Since springs are flexible and external forces tend to tilt the ends, grinding to an extreme level of squareness can be difficult. A spring may be specified for grinding square in the unloaded condition or square under load, but not in both conditions with any degree of accuracy. When squareness at a specific load or height is required, it should be specified.

Additional Spring Design Resources:

Compression Spring Design and General Considerations

Compression Spring Basic Features

Spring Materials

Spring Coatings and Surface Treatments

Sign Up/Log In

Sign Up/Log In

.png)