How to Measure a Torsion Spring

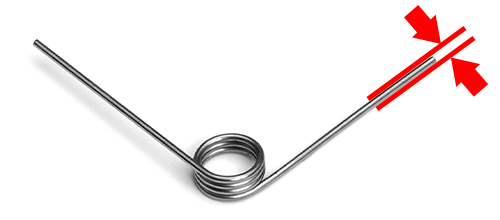

1. Measure the spring wire diameter, preferably to 3 decimal places for accuracy using calipers.

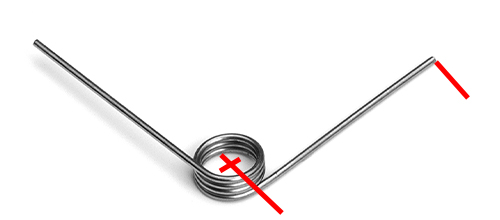

2. Measure the outside diameter of the coils. This might vary slightly from coil to coil, take the average value at the central coils of the body.

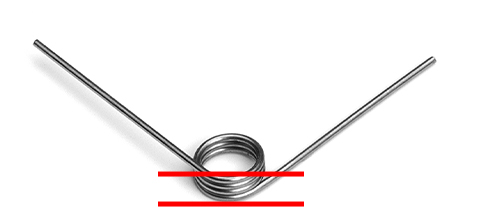

3. Measure the leg lengths of the spring. For standard legs this is from the centerline of the spring to the end of the leg. Repeat this step for the second leg if that side is different.

4. Measure the body length by taking the overall end-to-end length of the coil stack.

5. Count the total coils, start where the leg leaves the spring’s body going into the spiral. Count all full coils until you reach the other leg, include any fractions of a coil.

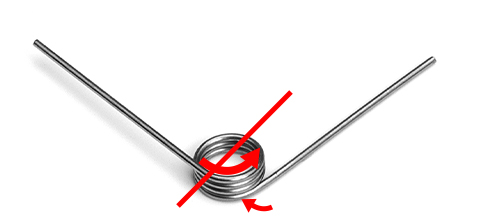

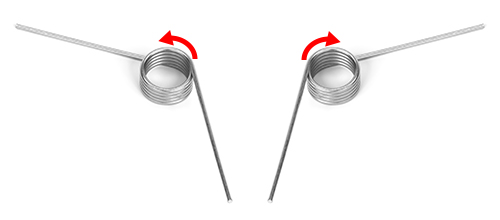

6. Measure the free position between the legs. Typical specification include: 90°, 180°, 270°, or 360° degrees. Special assemblies may require in-between values.

90 Degree Angle

180 Degree Angle

270 Degree Angle

360 Degree Angle

7. Note the winding direction of the coils. In most applications this is not important, but review surrounding parts and whether they require the spring to be in a specific direction.

8. Determine the spring wire material type. If the wire is not attracted to a magnet, then it might be a special metal alloy that needs exact identification. If the material is unknown, then take note of any extreme operating conditions such as: very high or low temperatures, presence of corrosive materials or rapid cycling. Learn more about Materials, and Spring Coatings and Surface Treatments.

Sign Up/Log In

Sign Up/Log In

.png)