Flat Springs: Complete Guide

What Are Flat Springs?

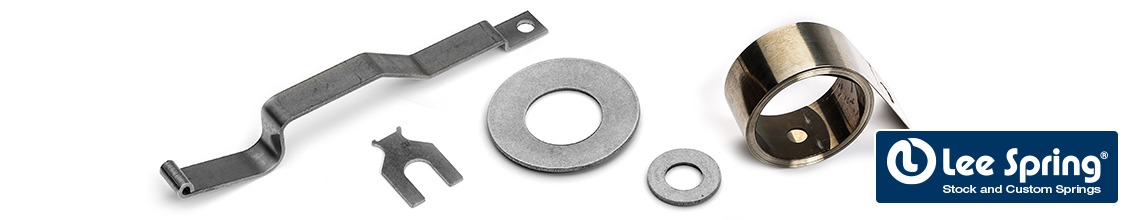

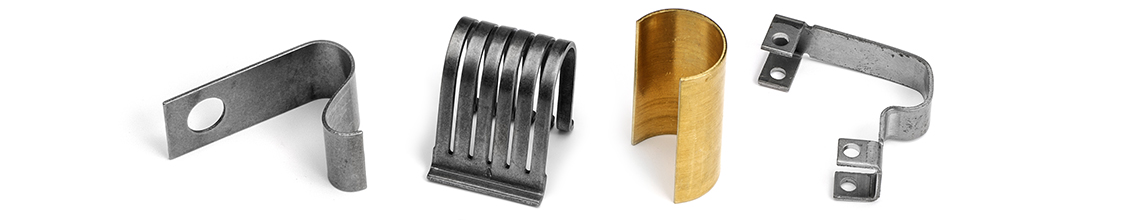

Flat springs are essential mechanical components that store and release energy through elastic deformation. Unlike coil springs that operate through torsional stress, flat springs work primarily through bending stress, making them ideal for applications requiring precise force delivery in compact spaces. These versatile components are manufactured from flat strips of spring steel and can be formed into various configurations to meet specific engineering requirements.

Made of flat strip steel, flat springs are ideally suited for applications where space is limited or where the spring can be used as part of a mounting assembly. The flat spring design allows forming of specific features and profiles for unique applications and mounting locations, making them incredibly versatile for custom solutions.

Types of Flat Springs

Cantilever Springs

These springs are fixed at one end and free at the other, operating like a diving board. Cantilever springs are frequently used in switches, relays, and precision instruments where controlled deflection and reliable return force are critical. Their simple design makes them cost-effective and easy to manufacture with consistent performance characteristics.

Simple Beam Springs

Supported at both ends with the load applied at the center, beam springs provide excellent stability and predictable deflection patterns. They are commonly found in weighing scales, pressure sensors, and mechanical testing equipment where accurate force measurement is essential.

Belleville Springs (Disc Springs)

Also known as conical disc springs, Belleville springs are formed into a conical shape that provides high force in a compact axial space. They excel in applications requiring high loads with minimal deflection, such as bolt preloading, clutch assemblies, and safety valve mechanisms. These are available as stock items in both imperial and metric sizes to fit common bolt sizes.

Wave Springs

These springs feature a wavy pattern that allows them to function in radial or axial compression. Wave springs are particularly useful in bearing preload applications, sealing systems, and anywhere space constraints require a low-profile solution with consistent force output. Lee Spring offers a stock selection of REDUX™ Wave Springs in many size configurations.

Constant Force Springs

Flat wound constant force springs provide nearly constant force throughout their deflection range. These specialized springs are ideal for applications requiring consistent force over extended travel distances.

Leaf Springs

The most recognizable type of flat spring, leaf springs consist of multiple layers of spring steel strips of varying lengths. Single-leaf springs offer simpler construction, while multi-leaf configurations distribute loads more effectively across the spring assembly.

Common Applications

- Electrical contacts - Providing reliable electrical connections

- Leaf springs - Traditional automotive suspension components

- Cantilever spring applications - Switches and control mechanisms

- Disc washers - Load distribution and preloading

- Hold-downs - Securing components in assemblies

- Clips - Fastening and retention systems

- Shims - Spacing and adjustment applications

Materials and Manufacturing

Material Selection

Spring steel remains the most common material for flat springs due to its excellent elastic properties and fatigue resistance. Commonly used materials include:

- Carbon steel - Good strength and durability for general applications

- Stainless steel - Corrosion resistance for marine, food processing, and medical applications (300 Series and 301 Series available)

- Spring steel alloys - Enhanced performance in demanding environments (51CrV4/AISI 6150)

- Brass and copper - Electrical conductivity applications

- Phosphor bronze - Electrical contacts and corrosion resistance

- Beryllium copper - High strength with electrical conductivity

- Various nickel alloys - Extreme temperature and specialized environments

Learn more about Spring Materials

Manufacturing Processes

Flat springs are manufactured through several key processes:

Primary Operations:

Blanking - Cuts spring material to required outline shape from sheet or strip stock

Forming operations - Bend, curve, or shape the spring to achieve desired geometry

Progressive die stamping - High-volume production with automatic presses

Secondary Operations:

Heat treatment - Hardening and tempering develop necessary spring properties and stress relief

CNC machining - Precision features and tight tolerances

Surface treatments - Shot peening, zinc plating, or powder coating for enhanced fatigue life and corrosion protection

Vibratory deburring - Smooth finish and edge preparation

Painting, welding, and assembly - Final finishing operations

Manufacturing Capabilities:

- Strip Width: up to 3" (76.20 mm)

- Strip Thickness: 0.003 to 0.125" (0.08 mm – 3.18 mm)

- Advanced quality control systems

- CAD-assisted product and tooling design

- Wire EDM for precision tooling

- Process validation including first articles and PPAP's

Design Considerations

Force and Deflection Calculations

The relationship between applied force and resulting deflection is fundamental to flat spring design. For cantilever springs, the deflection formula involves the applied load, beam length cubed, elastic modulus, and moment of inertia. Beam springs follow similar principles but with different geometric factors.

Stress analysis ensures the spring operates within safe limits to prevent failure. Maximum stress typically occurs at the fixed end of cantilever springs or at the center of beam springs. The material's yield strength and fatigue limits must be considered to achieve reliable long-term performance.

Geometric Parameters

Spring thickness directly affects both the spring rate and maximum stress. Doubling the thickness increases the spring rate by a factor of eight while reducing maximum stress by half.

Width changes affect the spring rate linearly and have minimal impact on stress levels. Length modifications significantly influence both deflection and stress characteristics. End configurations require careful consideration for proper mounting and load transfer. Common end treatments include eyes, hooks, holes, or specialized attachment features designed for specific applications.

Industry Applications

Automotive Industry

Flat springs serve numerous functions in automotive applications beyond traditional suspension systems. They are found in seat mechanisms, pedal assemblies, door handles, trunk latches, and various control systems. The automotive industry demands springs that can withstand millions of cycles while maintaining consistent performance under varying temperature and environmental conditions.

Electronics and Instrumentation

In electronic devices, flat springs provide reliable electrical contacts, precise positioning mechanisms, and user interface feedback. They are essential components in switches, connectors, battery contacts, and precision instruments where consistent force and minimal space requirements are critical.

Medical and Aerospace

These industries require springs with exceptional reliability and often specialized material properties. Medical devices may need biocompatible materials, while aerospace applications demand lightweight solutions with predictable performance across extreme temperature ranges.

Industrial Equipment

Manufacturing equipment, tools, and machinery rely on flat springs for various functions including clamping, positioning, vibration isolation, and energy storage. Industrial applications often emphasize durability and maintainability over other considerations.

Advantages and Limitations

Key Advantages

- Space efficiency - Flat profile ideal for applications with space constraints

- Excellent force-to-weight ratios - High performance in compact designs

- Specific force-deflection characteristics - Can be designed for precise requirements

- Economical manufacturing - Cost-effective production in large quantities

- Integrated mounting features - Simplifies assembly and reduces part count

- Inherent stability - Resistance to buckling under load

- Versatile forming capabilities - Custom shapes and features possible

Common Limitations

- Limited deflection capability - Compared to coil springs of similar size

- Fatigue susceptibility - Requires proper design for specific applications

- Manufacturing complexity - Complex shapes can be more expensive than simple coil springs

- Precision requirements - Some designs may require tighter manufacturing tolerances

Stock vs. Custom Solutions

Stock Flat Springs

Ready-to-ship options for same-day shipment include:

- Belleville Disc Springs - Available in 300 Series Stainless Steel and 51CrV4 spring steel, offered in both imperial and metric sizes

- Constant Force Springs - Available in 301 series Stainless Steel in imperial sizes

Custom Flat Springs

For unique applications, custom flat springs can be manufactured in a variety of shapes, sizes, designs, and materials. Advanced manufacturing capabilities include CAD-assisted design, prototype production services, and global supply chain support to create optimal designs for specific requirements.

Request a custom flat spring quote

Selection and Specification Guidelines

When selecting flat springs for an application, engineers must consider:

- Required force levels - Matching spring rate to application needs

- Deflection range - Ensuring adequate travel without overstress

- Operating environment - Temperature extremes, corrosive atmospheres, cleanliness requirements

- Space constraints - Physical limitations of the application

- Expected operating cycles - Service life requirements

- Material requirements - Regulatory compliance (RoHS, REACH, DFARS)

Environmental factors such as temperature extremes, corrosive atmospheres, or special cleanliness requirements may dictate specific materials or surface treatments. Cost considerations must balance initial spring price against expected service life and replacement frequency.

Working with Lee Spring early in the design process can help optimize spring design for both performance and manufacturability. Proper specification of tolerances, surface finish requirements, and quality standards ensures consistent performance in production applications.

Quality and Compliance

Modern flat spring manufacturing includes:

- ISO 9001:2015 certification - Quality management systems

- RoHS and REACH compliance - Environmental and safety regulations

- ITAR registration - Defense and aerospace applications

- Process validation procedures - Including first articles and PPAP's

- Extensive supplier networks - For raw materials, special processes, and production components

Flat springs represent a versatile and efficient solution for many mechanical design challenges. Their ability to provide precise force control in compact packages makes them indispensable across numerous industries. Whether choosing from stock options for immediate delivery or developing custom solutions for unique applications, flat springs offer excellent performance characteristics when properly designed and manufactured.

Success with flat springs requires careful attention to material selection, geometric design, and manufacturing processes to achieve optimal performance and reliability. Understanding the various types, design principles, and application considerations enables engineers to effectively incorporate flat springs into their designs while avoiding common pitfalls that can lead to premature failure or inadequate performance.

The combination of advanced manufacturing capabilities, extensive material options, and expert engineering support makes flat springs an ideal choice for applications ranging from simple hold-down clips to complex automotive assemblies and precision instrumentation.

Sign Up/Log In

Sign Up/Log In

.png)