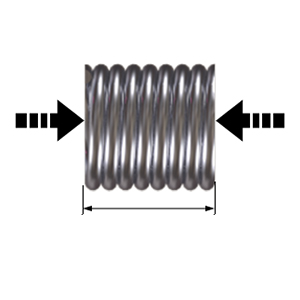

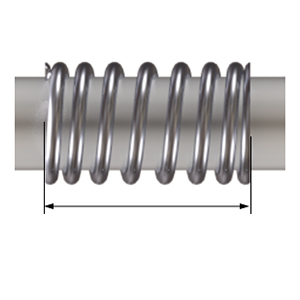

Compression Springs

Compression Springs are open-coil helical springs wound or constructed to oppose compression along the axis of wind. Easily search and find the right Compression Spring from thousands of designs available. Many Compression Spring series and material options available. Helical Compression Springs are the most common metal spring configuration. Learn more about Compression Springs and How to Measure a Compression Spring.

Results 16006 Springs

| Material | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

LHP 162J 01S

|

1.829 |

0.72 |

18.29 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

2.223 |

0.875 |

22.23 |

393580 |

39358 |

393.58 |

39.358 |

2203.94 |

3859.83 |

385.983 |

1.842 |

0.725 |

18.42 |

0.411 |

0.162 |

4.11 |

17-7 |

LHP 162J 02S

|

1.829 |

0.72 |

18.29 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

2.54 |

1 |

25.4 |

320801 |

32080.1 |

320.801 |

32.0801 |

1796.4 |

3146.09 |

314.609 |

2.073 |

0.816 |

20.73 |

0.411 |

0.162 |

4.11 |

17-7 |

LHP 162J 03S

|

1.829 |

0.72 |

18.29 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

3.175 |

1.25 |

31.75 |

234192 |

23419.2 |

234.192 |

23.4192 |

1311.41 |

2296.71 |

229.671 |

2.532 |

0.997 |

25.32 |

0.411 |

0.162 |

4.11 |

17-7 |

LHP 162J 04S

|

1.829 |

0.72 |

18.29 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

3.81 |

1.5 |

38.1 |

184407 |

18440.7 |

184.407 |

18.4407 |

1032.63 |

1808.48 |

180.848 |

2.995 |

1.179 |

29.95 |

0.411 |

0.162 |

4.11 |

17-7 |

LHP 162J 05S

|

1.829 |

0.72 |

18.29 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

4.445 |

1.75 |

44.45 |

152077 |

15207.7 |

152.077 |

15.2077 |

851.59 |

1491.42 |

149.142 |

3.457 |

1.361 |

34.57 |

0.411 |

0.162 |

4.11 |

17-7 |

LHP 162J 06S

|

1.829 |

0.72 |

18.29 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

5.08 |

2 |

50.8 |

129392 |

12939.2 |

129.392 |

12.9392 |

724.56 |

1268.94 |

126.894 |

3.919 |

1.543 |

39.19 |

0.411 |

0.162 |

4.11 |

17-7 |

LHL 750A 08

|

1.836 |

0.723 |

18.36 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

8.89 |

3.5 |

88.9 |

9821.9 |

982.19 |

9.822 |

0.9822 |

55 |

96.32 |

9.632 |

4.14 |

1.63 |

41.4 |

0.267 |

0.105 |

2.67 |

MW |

LHL 750A 09

|

1.836 |

0.723 |

18.36 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

10.16 |

4 |

101.6 |

8929 |

892.9 |

8.929 |

0.8929 |

50 |

87.57 |

8.757 |

4.521 |

1.78 |

45.21 |

0.267 |

0.105 |

2.67 |

MW |

LHL 750AB 01

|

1.842 |

0.725 |

18.42 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

2.54 |

1 |

25.4 |

48752.3 |

4875.23 |

48.752 |

4.8752 |

273 |

478.11 |

47.811 |

1.651 |

0.65 |

16.51 |

0.284 |

0.112 |

2.84 |

MW |

LHL 750B 02

|

1.842 |

0.725 |

18.42 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

3.175 |

1.25 |

31.75 |

68753.3 |

6875.33 |

68.753 |

6.8753 |

385 |

674.26 |

67.426 |

1.981 |

0.78 |

19.81 |

0.318 |

0.125 |

3.18 |

OTCS |

LHL 750C 11

|

1.842 |

0.725 |

18.42 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

12.7 |

5 |

127 |

31430.1 |

3143.01 |

31.43 |

3.143 |

176 |

308.23 |

30.823 |

8.458 |

3.33 |

84.58 |

0.376 |

0.148 |

3.76 |

OTCS |

LHL 750C 12

|

1.842 |

0.725 |

18.42 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

13.97 |

5.5 |

139.7 |

28572.8 |

2857.28 |

28.573 |

2.8573 |

160 |

280.21 |

28.021 |

9.22 |

3.63 |

92.2 |

0.376 |

0.148 |

3.76 |

OTCS |

LHL 750C 13

|

1.842 |

0.725 |

18.42 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

15.24 |

6 |

152.4 |

25715.5 |

2571.55 |

25.716 |

2.5716 |

144 |

252.19 |

25.219 |

10.185 |

4.01 |

101.85 |

0.376 |

0.148 |

3.76 |

OTCS |

LHL 750C 17

|

1.842 |

0.725 |

18.42 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

30.48 |

12 |

304.8 |

12857.8 |

1285.78 |

12.858 |

1.2858 |

72 |

126.1 |

12.61 |

20.132 |

7.926 |

201.32 |

0.376 |

0.148 |

3.76 |

OTCS |

LHL 750A 02

|

1.842 |

0.725 |

18.42 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

3.175 |

1.25 |

31.75 |

23215.4 |

2321.54 |

23.215 |

2.3215 |

130 |

227.67 |

22.767 |

1.549 |

0.61 |

15.49 |

0.249 |

0.098 |

2.49 |

MW |

LHL 750A 03

|

1.842 |

0.725 |

18.42 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

3.81 |

1.5 |

38.1 |

20536.7 |

2053.67 |

20.537 |

2.0537 |

115 |

201.4 |

20.14 |

1.829 |

0.72 |

18.29 |

0.254 |

0.1 |

2.54 |

MW |

LHL 750C 14

|

1.849 |

0.728 |

18.49 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

17.78 |

7 |

177.8 |

22322.5 |

2232.25 |

22.323 |

2.2323 |

125 |

218.92 |

21.892 |

11.836 |

4.66 |

118.36 |

0.376 |

0.148 |

3.76 |

OTCS |

LHL 750C 15

|

1.849 |

0.728 |

18.49 |

1.905 |

0.75 |

19.05 |

0.953 |

0.375 |

9.53 |

20.32 |

8 |

203.2 |

19643.8 |

1964.38 |

19.644 |

1.9644 |

110 |

192.65 |

19.265 |

13.36 |

5.26 |

133.6 |

0.376 |

0.148 |

3.76 |

OTCS |

LCD250JK 01 M

|

1.85 |

0.728 |

18.5 |

1.91 |

0.752 |

19.1 |

1.29 |

0.507 |

12.9 |

2.75 |

1.083 |

27.5 |

28299 |

2829.9 |

28.299 |

2.8299 |

158.467 |

277.53 |

27.753 |

1.375 |

0.541 |

13.75 |

0.25 |

0.098 |

2.5 |

MW |

LCD250JK 02 M

|

1.85 |

0.728 |

18.5 |

1.91 |

0.752 |

19.1 |

1.29 |

0.507 |

12.9 |

4.1 |

1.614 |

41 |

17999.3 |

1799.93 |

17.999 |

1.7999 |

100.791 |

176.52 |

17.652 |

1.875 |

0.738 |

18.75 |

0.25 |

0.098 |

2.5 |

MW |

Pagination

.png)

Sign Up/Log In

Sign Up/Log In