Spring Design: Compression Spring Set

Compression spring set is a change in the free height when a spring is compressed and released for the first time. Upon first compression of a spring, if the stress in the wire is high enough at the point the spring is compressed, the spring will not return to its original height and will be shorter after this first compression. This is referred to as the compression spring “taking a set” or “setting” a compression spring.

There are two primary approaches for handling the change in free height in a compression spring design due to the natural occurrence of compression spring set. These two approaches should be considered in the design of the compression spring and can impact the manufacturing process and cost of the spring.

The following compression spring design considerations are two methods for handling compression spring set.

Presetting or Removing the Set

Presetting or removing the set from a spring is an additional manufacturing process where the spring is compressed to solid height one time to ensure free height is correct for use. This process can add additional cost to the spring manufacturing process but may be a needed step depending on the application.

Allow for Set

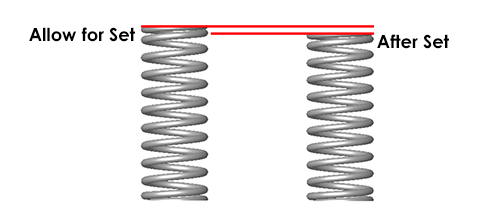

When a compression spring is supplied longer than specified to compensate for length loss when compressed initially, this is referred to as “Allow for Set”. To ‘allow for set’ means that the design of the compression spring compensates for length loss when fully compressing a spring for the first time. This length loss can occur during an initial installation of a spring into an assembly. It is suggested to reduce costs for large quantity orders to design the spring to ‘allow for set’, so a secondary spring setting operation is not required.

A ’set’ compression spring’s new free length will be stable and consistent through future compression cycles. The spring will generally not take any significant additional set from subsequent compressions.

There are many design considerations to review when working with and designing a custom spring. To learn more about spring design or for additional technical information visit our resource center, download our Compression Spring Design and General Considerations and Compression Spring Basic Features guides for more information.

Sign Up/Log In

Sign Up/Log In

.png)